Choosing the right cable solution is critical when designing or...

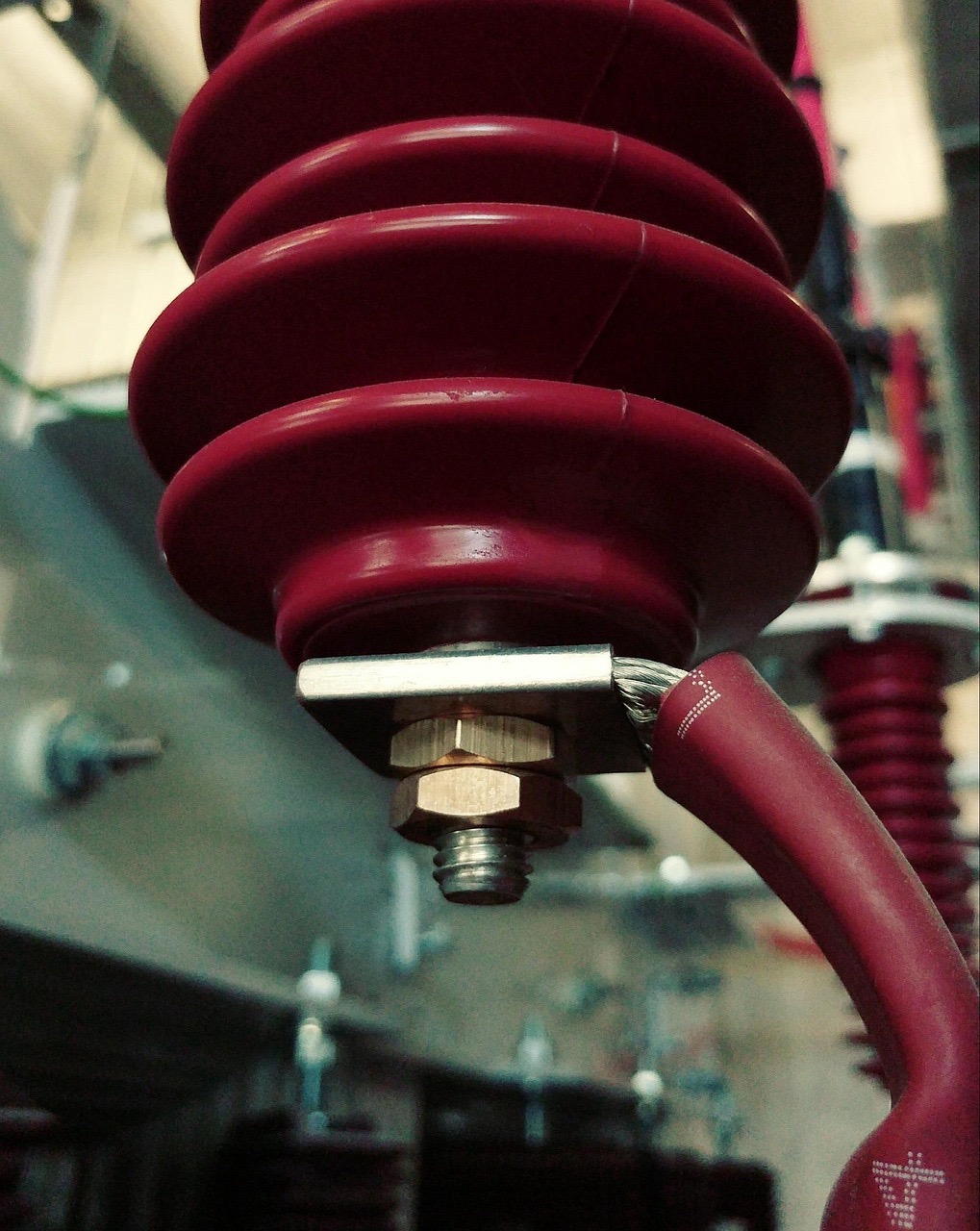

Cable Assemblies for the High Voltage Industry

High Voltage Cable Assemblies for Demanding Industry Applications

UK & Worldwide

Reliable, Custom High-Voltage Wiring Solutions for Industrial, Automotive & Energy Sectors

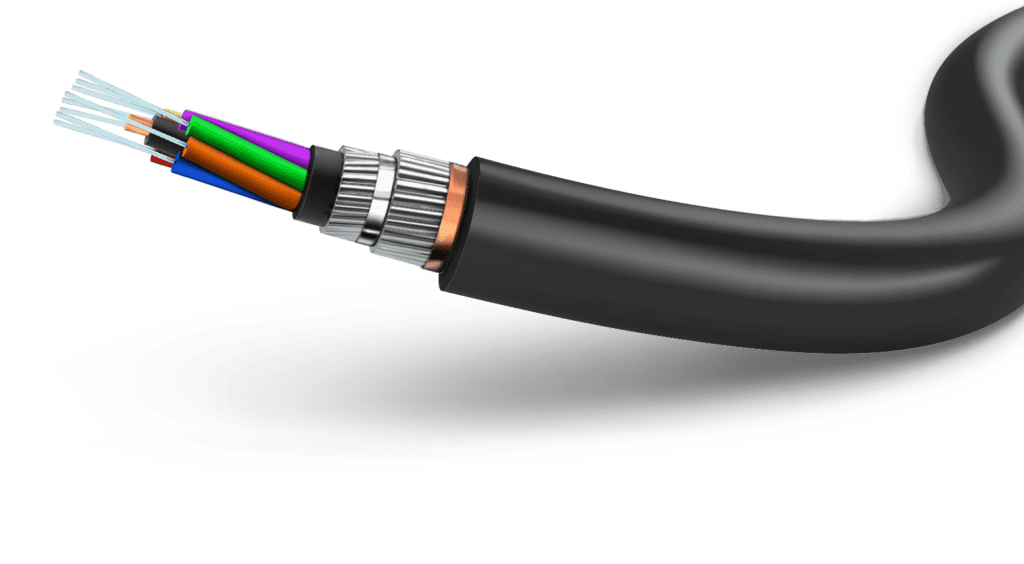

High-voltage cable assemblies are essential in applications where power, safety, and durability are critical. At Cablepoint, we specialise in custom-engineered high-voltage cable solutions, delivering precision, reliability, and compliance across industries such as electric vehicles (EVs), renewable energy, industrial machinery, and aerospace. From battery management systems to power distribution networks, our high-voltage wiring harnesses ensure maximum efficiency, safety, and longevity under extreme conditions.

Compliance

Exacting compliance, with quality at the heart of everything we do

Reliability

We've been manufacturing cable assemblies for our clients since 1991

Sustainability

Sustainability is at the heart of everything we do

Local Service, Global Delivery

From small projects for local SMEs, to global businesses

Why High Voltage Cable Assemblies Matter

Handling high-voltage power requires specialist expertise, ensuring that cables are properly insulated, heat-resistant, and capable of withstanding harsh environments. Poor-quality cables can lead to power loss, overheating, and electrical failures, which can compromise safety and system performance. At Cablepoint, our high-voltage cable assemblies are designed, manufactured, and rigorously tested to meet industry standards while offering:

- High power transmission, ensuring efficient energy transfer with minimal loss.

- Superior insulation and shielding to protect against voltage leaks, electromagnetic interference (EMI), and electrical discharge.

- Temperature and environmental resistance, capable of withstanding extreme heat, cold, chemicals, and mechanical stress.

- Custom configurations tailored to exact voltage, length, and application-specific requirements.

- Long-term durability, built for reliability in harsh industrial and automotive environments.

Applications of High Voltage Cable Assemblies

Our high-voltage wiring solutions serve critical industries that demand safe, durable, and high-performance power transmission.

Electric Vehicles & Automotive

- EV powertrain and battery management systems, ensuring reliable, high-voltage connections for EV battery packs, motors, and charging systems.

- High-power charging cables for fast-charging stations and onboard charging units.

- Autonomous and hybrid vehicles, ensuring uninterrupted power flow to self-driving technologies.

Renewable Energy & Power Distribution

- Solar and wind power systems, with heavy-duty, high-voltage cables for solar farms, wind turbines, and battery storage solutions.

- Grid and substation connections, using insulated, reinforced cables designed for high-voltage transmission networks.

Industrial & Automation

- High-voltage wiring for robotics, conveyor systems, and automated machinery.

- Power distribution solutions for heavy industrial equipment and high-load applications.

- Cables designed for harsh environments with resistance to extreme temperatures and chemicals.

- Custom harnesses for power-intensive manufacturing and processing equipment.

Aerospace & Defence

- Aircraft and space systems, providing high-performance wiring solutions for aviation and spacecraft power distribution.

- Military-grade high-voltage cables, designed for defence applications with extreme durability and reliability requirements.

Medical & Healthcare

-

- High-voltage medical-grade cables for MRI, CT scanners, and X-ray imaging systems.

- Insulated power cables for life-support equipment and surgical devices.

- Shielded high-voltage wiring for electrosurgical tools and laser-based medical treatments.

- Reliable, low-interference cables for radiotherapy machines and high-frequency medical applications.

Custom Cable Assemblies for a Wide Range of Applications

Our team of IPC-trained specialists has extensive experience in manufacturing all types of cable assemblies, including:

Custom Cable Assemblies: We design and build cable assemblies to your exact specifications, from simple stripped and crimped wires to complex soldered connections and PCB assemblies.

- Cable Preparation Services: Our team can expertly prepare your cables for assembly, including stripping, crimping, and terminating.

- Solder Assemblies: We utilise high-quality soldering techniques to ensure reliable and long-lasting connections in your cable assemblies.

- Crimp Assemblies: We offer precise crimping services for a secure and dependable connection.

- Moulded Cable Assemblies: We can create custom moulded cables for specific applications requiring environmental protection or strain relief.

- Rapid Prototyping: our expertise can support your rapid prototyping projects with custom cable solutions designed for swift iteration and testing phases.

- Electronic Connectors: We offer a wide selection of electronic connectors to meet the diverse needs of your project.

- Ribbon Cable Assemblies: We manufacture high-quality ribbon cable assemblies for applications requiring multiple connections in a compact space.

- Drag Chain Assemblies: We design, and build drag chain assemblies that can withstand the constant flexing and movement found in robotic and automated applications.

- Telecom & Data Cable Assemblies: We provide reliable and high-performance cable assemblies for telecommunication and data transmission applications.

Read about our complete manufacturing and testing process.

We have a proven track record of delivering exceptional results across various industries, and our team is always up to date on the latest industry standards and regulations, supporting small businesses and global enterprises.

We work collaboratively with you to understand your project’s exact specifications and ensure the resulting cable assemblies meet or exceed your expectations in terms of:

- Performance: We use high-quality materials and components to create cable assemblies that deliver optimal performance in even the most demanding applications.

- Reliability: Our rigorous manufacturing processes and stringent quality control procedures guarantee the consistent reliability of every cable assembly we produce.

- Efficiency: We manufacture cable assemblies to help optimise efficiency within your systems.

Customer Testimonials

Why Choose Cablepoint as Your Cable Assembly Company?

- Uncompromising Quality: With rigorous quality control processes and adherence to international standards, we deliver products of exceptional quality. Our commitment to excellence ensures that every solution we provide is built to last and perform reliably.

- Decades of Experience: Established for over 30 years, Cablepoint brings a wealth of industry knowledge to every project. Our experts have tackled diverse challenges across various sectors, ensuring that you benefit from our deep pool of experience.

- Timely Delivery: We understand the importance of deadlines and strive to deliver your solutions on time, every time.

- Global Reach: While proudly based in the UK, our services extend worldwide. We have the capability to deliver our custom cable assemblies throughout the UK and across the globe.

- Sustainability: We’re committed to environmentally responsible practices, using eco-friendly materials and processes wherever possible. Our sustainable approach ensures that your cables are not only effective but also align with global environmental goals.

- Dedicated Support Throughout Your Project: We understand that clear communication and ongoing support are crucial for a successful project. That’s why we work closely with you throughout the entire cable assembly process, from the initial consultation to final production and delivery.

Discuss Your High Voltage Cable Requirements with Our Team

Looking for custom-engineered, high-performance High Voltage cable assemblies? Cablepoint is your trusted partner.

Call us today to speak with a High Voltage cable specialist or request a quote for your project requirements.

Industry Compliance & Certifications

We understand that high-voltage power systems require strict adherence to industry regulations. Our cables are manufactured to meet or exceed:

- IPC/WHMA-A-620 – Standards for high-reliability wiring harnesses.

- ISO 9001 & ISO 14001 – Certified quality and environmental management.

- UL & CE Compliance – Ensuring global safety and regulatory approval.

Every high-voltage cable assembly undergoes rigorous testing, including:

- Dielectric withstand testing, ensuring insulation integrity under high voltages.

- High-voltage continuity testing, verifying uninterrupted power transmission.

- Environmental stress testing, assessing performance in extreme heat, cold, and humidity.

High-Speed Cable Assemblies for Optimal Data Transfer

Reliable and efficient data transmission is crucial. Cablepoint specialises in designing and manufacturing high-speed cable assemblies that meet the stringent requirements of modern applications. Our expertise in selecting the right materials, connectors, and assembly techniques ensures optimal performance and signal integrity.

Key benefits of our high-speed cable assemblies:

- Low signal loss

- High data transfer rates

- Reduced electromagnetic interference (EMI)

- Durability and reliability

Whether you need high-speed cable assemblies for data centres, networking equipment, or industrial automation, we have the solutions to meet your needs.

Our Production Capabilities

From simple wiring looms to complex harnesses, we can produce any required quantity. We also offer a refurbishment option on products, if required.

We produce a wide range of box build and control panels for a number of industries - from pharmaceutical to boiler manufacturers.

We have custom overmould and potting facilities on site. Depending on the cables required, the cost of any tooling can be amortised across your contract.

Our team is IPC trained, with experience producing a wide range of cable assemblies. From simple stripped, tinned, bootlaced and crimped wires to soldered wires and PCB connection.

We provide initial, pre-production cables to ensure complete accuracy, followed by full batch production. Customers may also use this facility for engineering prototypes and design ‘first-offs’.

We have two automated terminating machines with a tinning facility, enabling quality crimped wires to be produced economically and efficiently in large volumes.

Our clean room facility facilitates the production of high end F.O.D (Foreign Object Debris) sensitive specialist cables.