Equipment & Facilities

Moulding Machine / Potting Facilities

A Boy Procan Alpha 2 services the moulding of connectors, providing a water tight seal; Injection moulding and over moulding. Potting facilities and our own engineering facilities to produce custom jigs provide an alternative process.

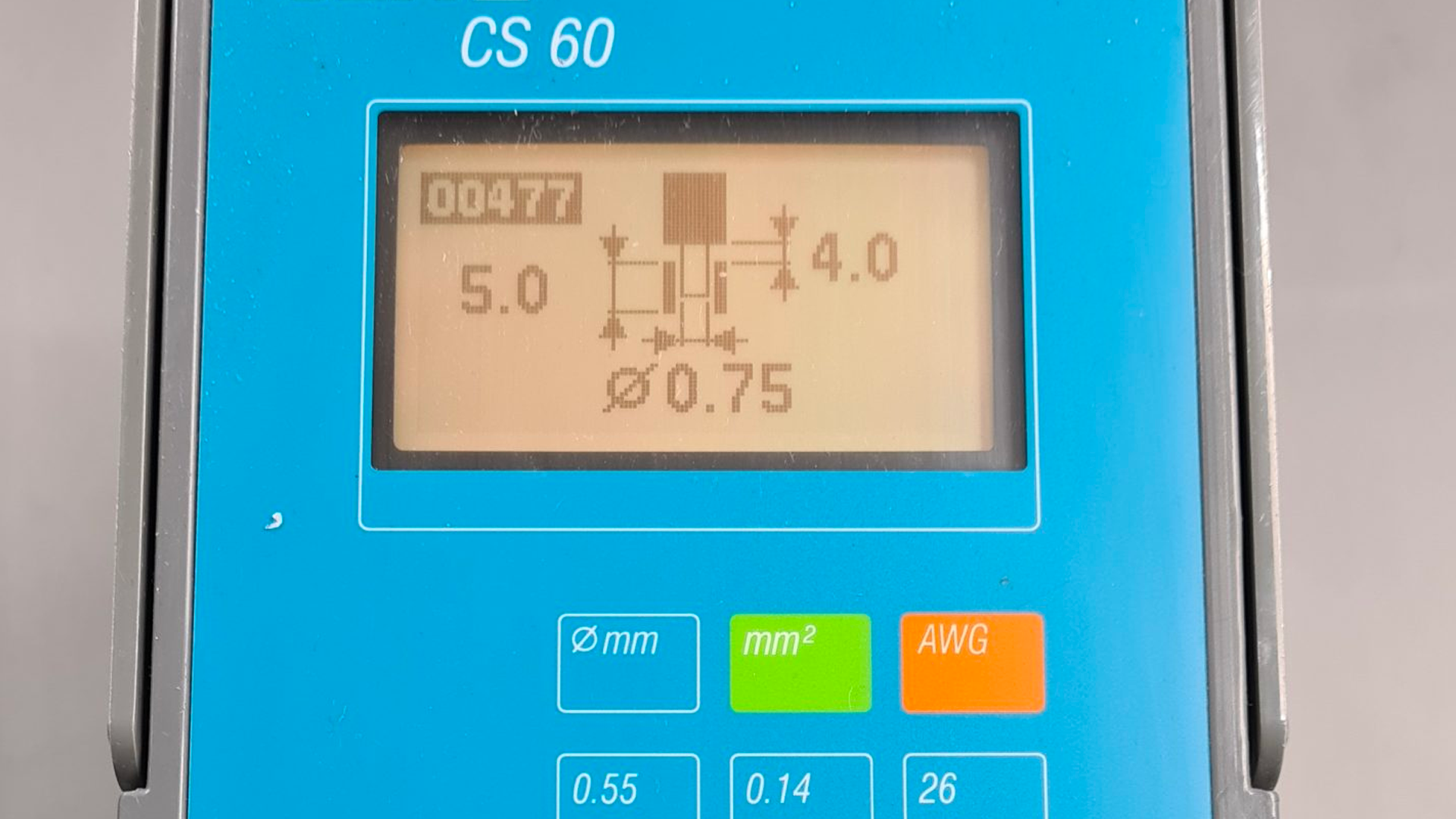

GLW Stripping Machines CS 60’s

The shortfeed in lengths facilitates fast and accurate work. The clamping force of these machines is automatically adjusted to the stripping force preventing indentations on some of the more sensitive insulations. The screen allows accurate strip lengths & gauge depths to be set (10-26 AWG).

Automatic Termination/Tinning Equipment

The Artos & JST automatic termination machines have the ability to crimp very small terminations in large volumes as well as other crimps. We are also able to accuratly cross large volumes of wires efficiently and accurately.

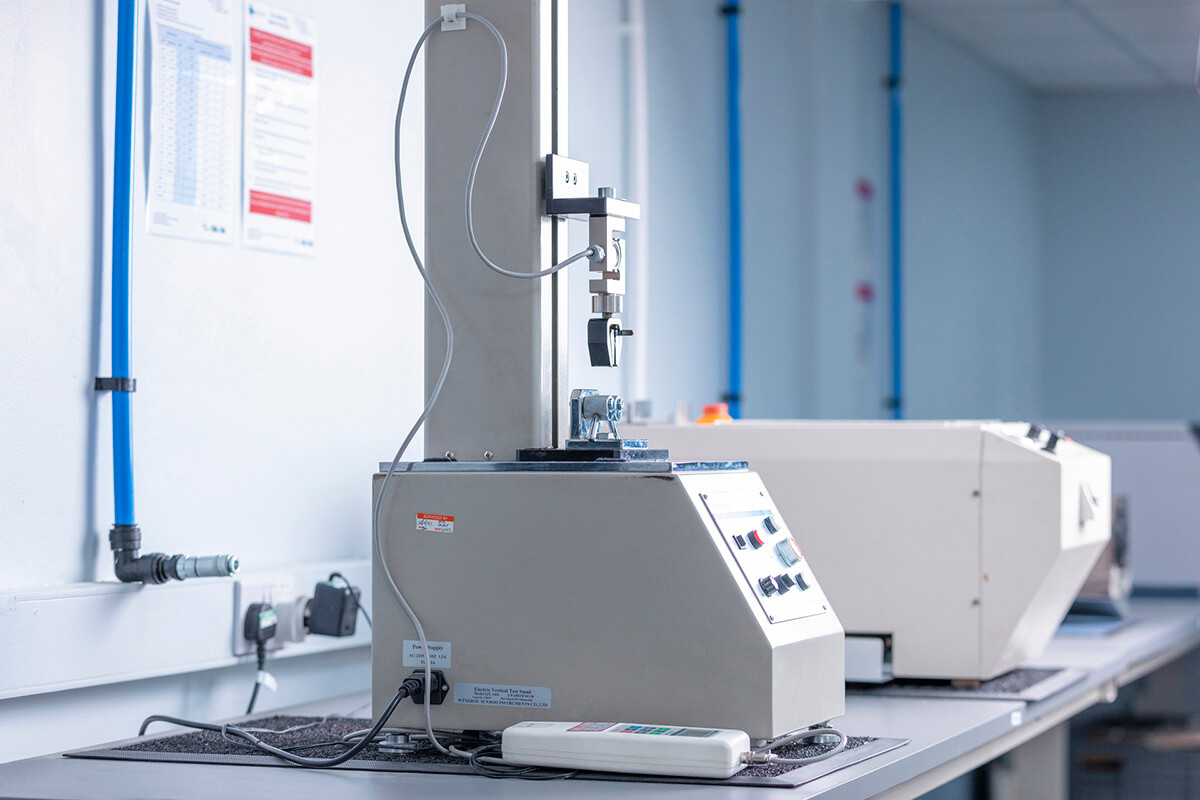

SPC Machines

Used to test the force required on all crimping. A Sundoo, Newtons are applied according to UL & SAE AS 57928 requirements, stranding & AWG

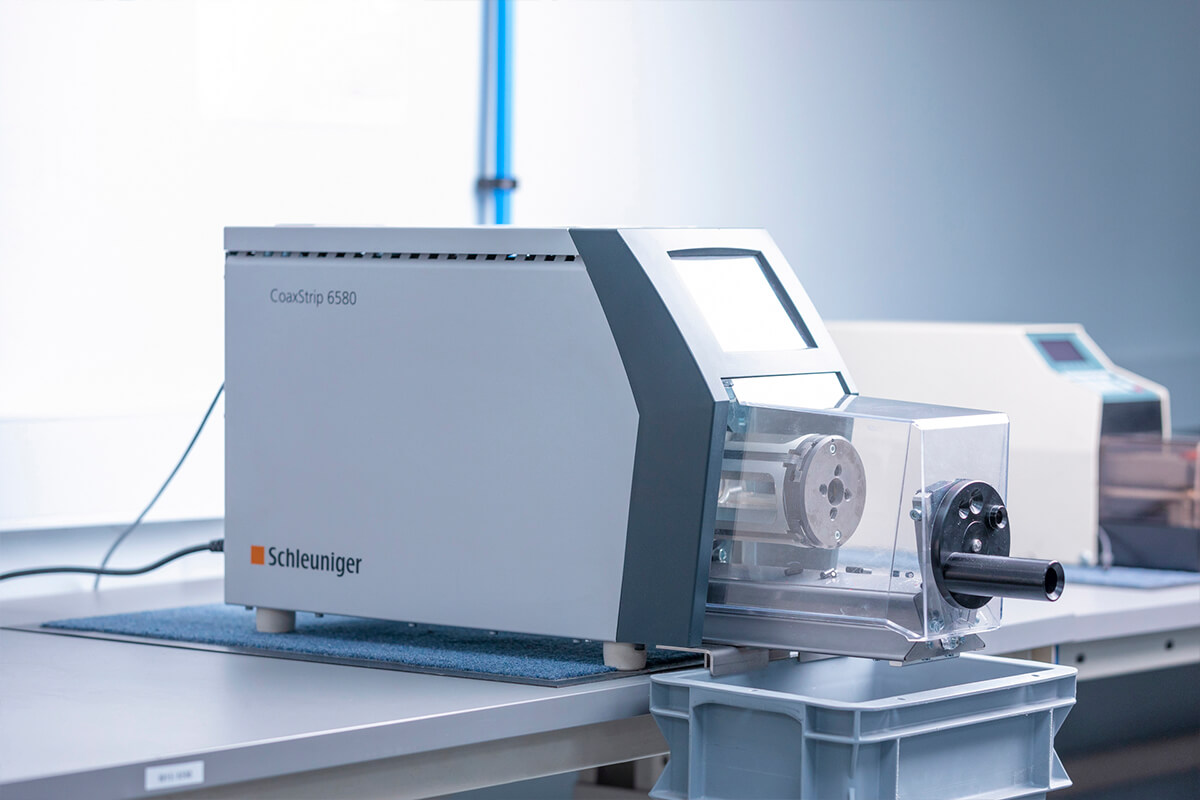

Bench Strip and Crimp Machines

Schleuniger jacket strippers 2600, 6580, 8015 & 8400 provide us with the capability to process a range of crimps, Kadera cut and strip machines to facilitate the accurate cutting & stripping of the outer jacket or inner insulation whatever your requirements. A number of machines are used for different applications.

Test Equipment

Cimbian testers are used to map each connection of an individual cable and identify incorrect build. The CableEye HVX system can be adjusted at 1 Volt increments from 10V to the maximum voltage permitted, allowing for complete control over ramp up, ramp down, dwell time, trip current & trip delay (soak time).